Prefab Cabin Shells: The Ultimate Solution for Building Your Dream Cabin

Prefab Cabin Shells: Building Your Dream Cabin Prefab Cabin Shell is the ultimate solution for your dream cabin.

If you’ve ever dreamed of owning a cabin in the woods, on a lake, vacation homes or in the mountains, then you know how difficult and time-consuming the building process can be. But what if there was a way to simplify the process?

What if you could have a cabin that is not only affordable but also easy to build? That’s where cabin shells come in.

When you purchase a cabin shell from a true cabin builder, you can have peace of mind that you are starting your finish out project with a structure worthwhile of your time, and talents! This allows you to create the perfect size cabin and design for your way of life.

Make a list

Cabin shells are an investment of not only money but your time if you are finishing them out, so you must ensure that as you consider a cabin shell, you make a list with your ‘must haves’.

This list should address items such as having enough space in the cabin shell, the square feet, the number of windows, bathroom location, and where your walls will go.

Continue your list with how you want to finish the cabin, as this goes hand in hand with your layout.

If you are adding items such as a kitchen, let your cabin shell builder know, as they sometimes can rough in the plumbing, so your outlets will end up being counter-height. Your kitchen window is the right size and placement for your future finish-out plans for your cabin shell.

Site prep and other factors to consider when purchasing a factory-built cabin shell.

All cabin shells need a good pad or foundation.

All cabin shells need a good pad to prevent leveling issues with your cabin that are not covered under most cabin shell warranties. Site leveling and preparation are the purchaser’s responsibility. Proper pad preparation is essential.

Check with your local building authorities on what type of foundation or pad site you can have for your property.

With your foundation or pad site, some areas will require that your cabin shell has an engineered foundation to support the cabin. These are easy to obtain by working with a local engineer familiar with the foundation requirements for your area.

If your property does not require an engineered foundation, options include a full concrete pad or a road base foundation pad depending on the size of the cabin and your ground conditions. Road base pad sites are the easiest and a good option for smaller cabin shells.

It is always best to check with a local engineer or contractor familiar with your ground conditions. Checking with the local building division is a good way to start so you do not get to partway through your project to find out your foundation needs to be different.

Sewer and Water connections

Other things to consider would be putting in a well if you are not connected to co-op water or city water and ensuring that you have electricity to your existing property.

This would also apply to sewer – a septic system is needed if you are not hooking into city septic systems.

Site access for a factory-built cabin shell delivery

Factory build cabin shells are delivered to your address on a truck and trailer from the cabin builder factory. For this to be successful, you, as the land owner, need to ensure the following checklist items are in good order before delivery:

Checklist:

- Good access to delivery

- Ground surface level

- The Pad site was prepared before cabin delivery

- Stable ground conditions

- Any obstructions such as fences, gates, low hanging branches should be removed before delivery

- Have an 811 survey before any anchoring that will be needed or installation of new septic or water lines.

- Verify what type of foundation/pad is required by state and local government.

Delivery Methods for your Cabin Shell

Most deliveries will be by an offload method, where the truck will pull over your foundation or back onto your foundation and then pull forward as the cabin shell is being set on blocks. Another common method is a crane set cabin shell. This is when a crane will lift the cabin shell off the truck and set it directly on your foundation. This delivery method is needed if a truck can not back onto or pull onto your pad site.

What are Cabin Shells?

Cabin shells are pre-built structures built by cabin builders in a factory and delivered to your site. These structures come in various shapes and sizes and can be customized to fit your needs.

The shells include the main structural elements of the cabin, such as walls, roof, and floor, but do not include any interior finishes or fixtures.

Some cabin builders will offer electrical rough-in, plumbing rough-in, frame-out interior cabin walls for you, and spray foam insulation.

There is some site prep to work on before having your cabin shell delivered, but one of the more important items to ensure is done correctly to prevent future leveling issues with your portable cabin.

What is not Prefab Cabin Shells?

A cabin shell that you are planning on living in, or using for a vacation property or short-term rental, needs to be constructed to residential codes for your area. Be sure to ask the company advertising and selling your factory-built cabin shell is building to residential codes that apply to your area.

Some items to look for are house wrap – cabin shells need to have house wrap on if the siding is installed, this is an easy item to spot quickly to see if the building you are buying for your cabin shell is to code.

Another item to look for is how the cabin shell is framed. Correct stud placements around windows and doors exist for jack studs, king studs, and cripple studs.

Next, how is the roof assembly? Is there a ridge beam, engineered trusses, or collar ties in the visible assembly? If the cabin shell salesperson can not tell you or point any of the above outs, go quickly away and find another cabin shell company to look at.

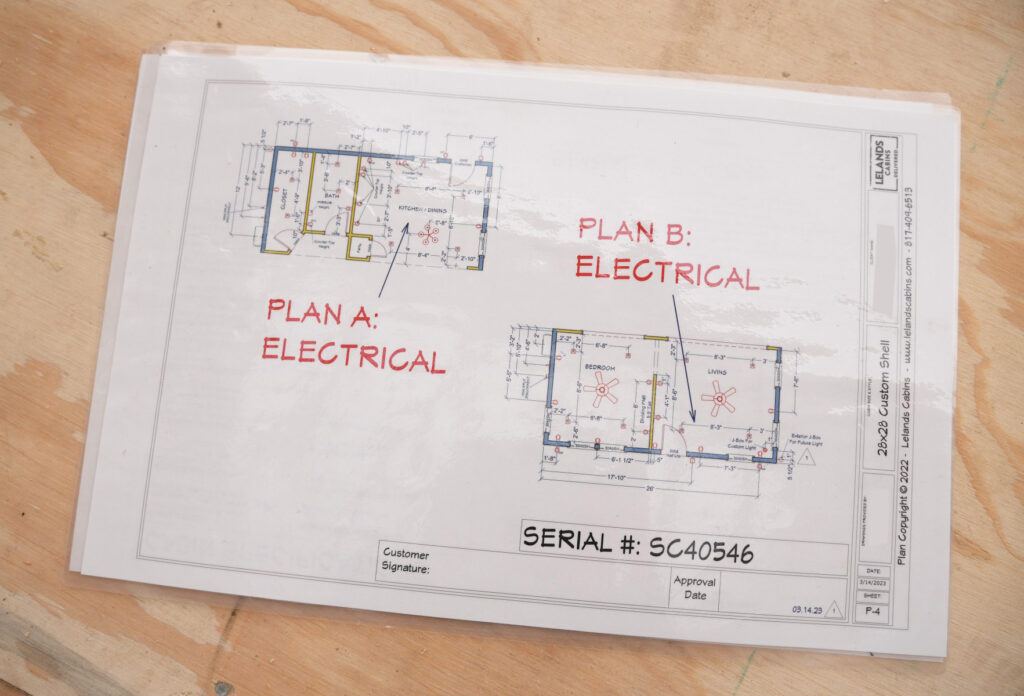

Electrical rough-in on your cabin shell

If you are looking at having the electrical rough-in completed, ask and verify that a licensed electrician or company installed the electrical and that it is done to the codes adopted by the state.

If you ask, “what codes are you installing the electrical to’ – the company that is following codes will be able to tell you which year of codes are for the area you will be having the cabin delivered to.

Expect an answer like “2020 NEC” or 2017 NEC”. NEC Stands for National Electrical Code.

As with any investment, do your homework on your cabin shell, and look into how the structure is built, the quality craftsmanship, and the design process to ensure you are buying a new cabin shell, not a new shed.

Benefits of Cabin Shells

There are numerous benefits to using cabin shells for your cabin-building project:

1. Cost-effective

Cabin shells are generally more affordable than traditional site built, also called stick-built homes, and are also less expensive than a finished-out cabin.

This is because the cabin shells are produced in a factory setting, which allows for greater efficiency and cost savings.

2. Time-saving

Since the cabin shells are pre-built in a factory, the on-site assembly time is greatly reduced compared to traditional stick-built cabins.

This means you can have your cabin from a cabin builder up and ready to use in weeks rather than months or years.

3. Customizable

Cabin shells can be customized to fit your specific needs and preferences. You can choose from various sizes, styles, and finishes to create the perfect cabin for your needs.

You then have the cabin shell to invest your talent and sweat equity in your finish-out project by adding walls, flooring, cabinets, and fixtures.

4. Energy-efficient

Many cabin shells are designed to be energy-efficient, which can help to reduce your energy bills and minimize your environmental impact.

Lofts are an option in most areas!

Cabin shells can also be built with lofts. Remember, since this is a cabin shell, the shell, and the loft space are unfinished.

If you have a loft built in – this will give you more options for space.

Depending on the roof pitch, which typically ranges from a 5/12 pitch to a 10/12 pitch, you can have a space from storage size in a 5/12 cabin roof pitch to a full-size, 8-foot ceiling height loft in a 10/12 roof-pitched cabin.

Prebuilt cabin shells with loft spaces and without are a more convenient and time-saving build if you have the talents and sweat equity to invest in your cabin project.

This can help you avoid site construction headaches and give you the dream cabin you have been looking for.

How to Choose the Right Cabin Shell

When choosing a cabin shell, there are several factors to consider:

1. Size

Consider the size of the cabin shell in relation to your needs and the available space on your site. Think about how many bedrooms and bathrooms you need and any additional features, such as a loft or deck.

2. Style

Various cabin styles are available, from traditional cedar-sided cabins to modern designs with a mono slop and board and batten cabin exteriors.

Choose a style that fits your taste and complements the surrounding environment. High ceilings and clean lines may be important to you, so pick a style that matches your cabin dream.

3. Materials

Prefab cabin shells can be made from various materials, including wood, steel, and concrete. Consider each material’s durability, cost, and environmental impact before deciding.

4. Cabin shell Manufacturer

Research the cabin manufacturer of the cabin shell to ensure that they have a good reputation and offer high-quality products.

Look for a company that builds residential code and backs their plans with engineering.

The trending ‘shed to home’ slogan is catchy, but if you are trying to invest in a cabin shell to live in, ensure you are buying from a reputable cabin company that understands building codes and follows them.

How to prepare for a Cabin Shell

Preparing for a cabin shell is a relatively simple process. Here is a summary of the basic steps:

1. Site preparation

Prepare the site by leveling the ground and laying a foundation. The type of foundation will depend on the specific cabin shell you choose. The prefab cabin shell builder can offer guidance on on-site preparations.

2. Choose your cabin size, style, and exterior.

You can pick out the exterior of your cabin with the cabin builder – as well as roofing materials, paint or stain colors, and any decks that might be added.

3. Delivery and assembly

The cabin shell will be delivered to your site in one or two sections. If two sections, these will be bolted together on site.

You must ensure ample room for the delivery truck to offload the cabin or have your cabin set on your foundation with a crane or other equipment.

4. Interior finishing

Once the shell is assembled, you can begin to finish the interior. This may include insulation, drywall, plumbing, electrical, and flooring.

Be sure to do your cost analysis before purchasing your cabin shell so you have a good budget and have enough to complete your interior finishes.

Leland’s Cabins, America’s Premier Cabin Builder, builds cabin shells to residential codes.

At Leland’s Cabins, we can build a cabin shell from 216 square feet to over 3000 square feet. Our cabin shells are framed to your state building codes, and we offer electrical packages and insulation packages.

Exteriors can be finished with split cedar log siding, LP Smart Panel, Board, and Batten or Lap siding. We have even done cabins with metal siding.

Interior room frame-out is also an option and can be a huge time saver for your cabin shell project.

Contact us at 877-714-7878 for more information and how to order a cabin shell from Lelands’s Cabins.

Conclusion

Prefab cabin shells are an excellent solution for anyone looking to build a cabin quickly, affordably, and with minimal hassle. Cabin shells offer a wide range of styles and customization options available.

Cabin shells are a great investment for additional space, your main house, a tiny home, a man cave that you want to have double as a guest house or extra living area, a dream come true cabin in the woods for your existing land, or a new piece of property you are looking at buying.

Cabin shells let you finish the interiors and pick out your exterior finishes, such as metal for the roof, siding, and colors.

Cabins are an affordable housing option, and if you have the time and talent to finish cabins yourself, you can save money.